Westmor Introduces the Safest Side-Fill Design in the Market

FOR IMMEDIATE RELEASE

Westmor Introduces the Safest Side-Fill Design in the Market!

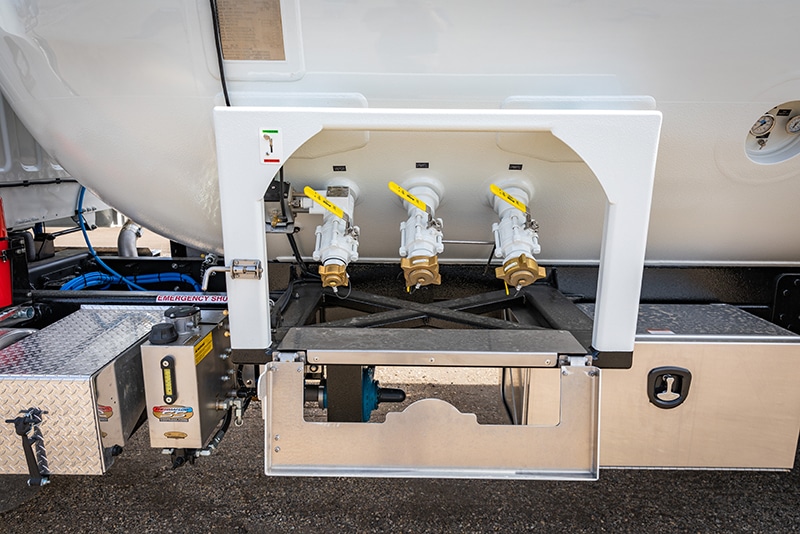

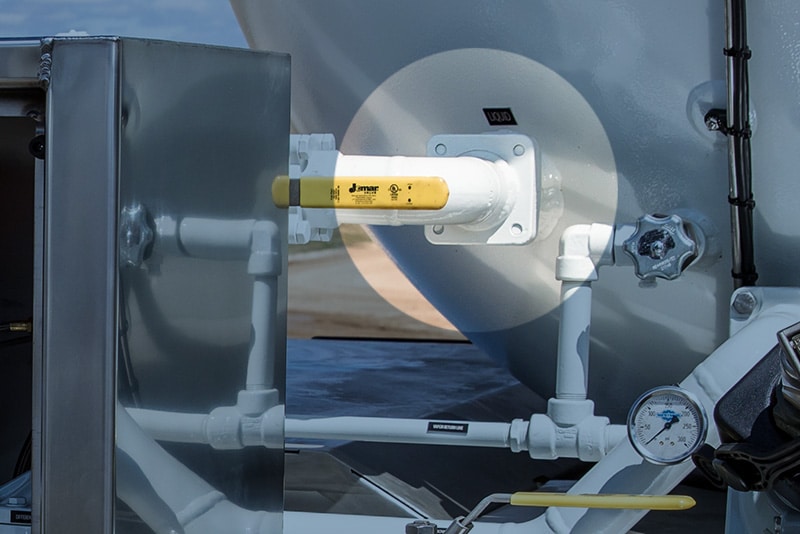

Morris, Minn. – Westmor Industries, LLC., one of North America’s most comprehensive energy storage, transportation, and dispensing equipment manufacturers and suppliers, announces their new side-fill design with the safest impact protection in the market. The impact protection exceeds US DOT and Transport Canada requirements.

Westmor’s side fill positions the sprayfill line(s) and vapor return line near the front of the tank in the shell with a simple interlock system. The recessed float gauge at the front of the tank provides better visibility while loading. Choose from options such as roadside or curbside loading connections or two sprayfill lines for faster load rates.

About Westmor Industries, LLC.

Headquartered in Morris, Minnesota, with satellite locations throughout the United States, Westmor Industries is a privately-owned company with more than 250,000 square feet of manufacturing space and 500 employees. Westmor supplies its customers with a diverse group of product offerings used to store, transport, and dispense petroleum, propane, and other liquids and gases from Pipeline to Pump®. In addition, Westmor provides customers with vast aftermarket support including parts sales, product repair, infrastructure installation, and in-field services.